Power Factor Correction

Power Factor Correction

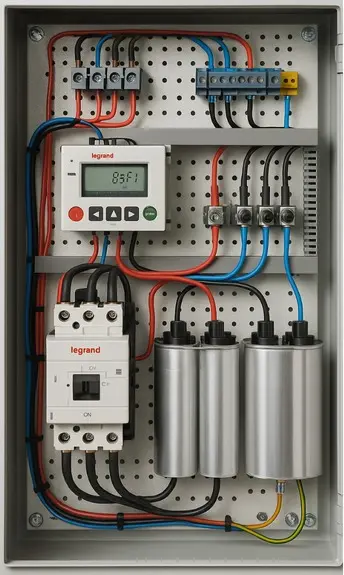

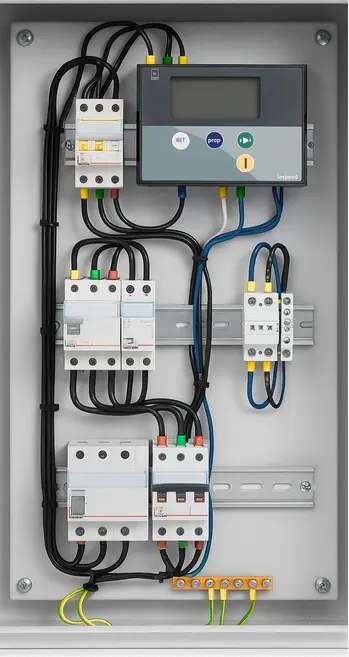

Power Factor Correction (PFC) Panels improve electrical system efficiency by maintaining the power factor near unity through automatic control of capacitor banks.

They are commonly used factories, workshops, HVAC systems, and pumping stations.

Main components: MCCB or MCB, APFC Relay, Capacitor Banks, Contactors, Fuses, Busbars, and a Painted Metal Enclosure.

Motor Control Panels are used to control and protect electric motors in industrial and commercial applications. They centralize motor operation, monitoring, and protection to ensure efficient performance and safe operation.

[5:27 pm, 27/11/2025] Triple M: Manufacturing plants, HVAC systems, water treatment stations, and pumping systems.

[5:27 pm, 27/11/2025] Triple M: Main Components: Circuit Breakers, Contactors,

soft starter PANELS

Soft Starter Panels are control panels designed to start electric motors smoothly by gradually increasing the voltage, reducing mechanical and electrical stress during startup.

Used in water pumps, HVAC systems, compressors, conveyors, and heavy industrial machines.

Main Components: Soft Starter Unit, Bypass Contactor, Bypass Contactor, Overload Relay, Control Components, Cooling System.

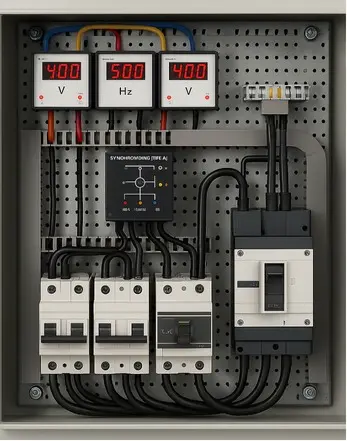

Synchronization Panels

Synchronization Panels are used to synchronize multiple power sources such as generators or transformers, ensuring balanced and stable power distribution.

They are commonly used power stations, generator rooms, factories, and data centers.

Main components: MCCB/ACB, Synchronizing Relay or Controller, Voltage & Frequency Meters, CTs/PTs, Control Relays, Busbars, and Metal Enclosure.

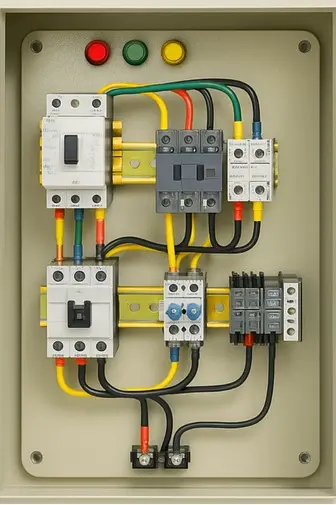

Direct On-Line (DOL panels )

Direct On-Line (DOL) panels are used to operate small and medium electric motors directly from the power supply without reducing the starting current.

They are used in electric pumps and irrigation systems, ventilation and air conditioning systems, simple production lines, and small elevators and hoists.

Main Circuit Breaker (MCCB or MCB) – Contactor – Thermal Overload Relay – Start/Stop Push Buttons – LED Indicators – Additional Protection Relays – Copper Busbars and Wiring – Painted Metal Enclosure.

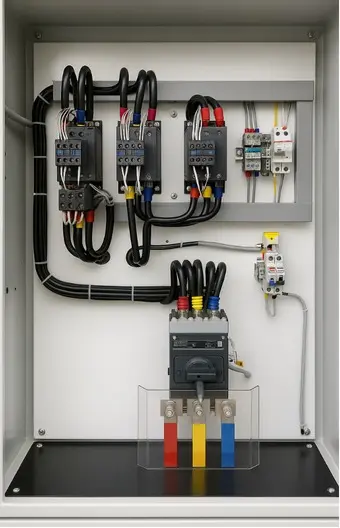

Star/Delta panels

Star/Delta Panels are used to operate medium and large electric motors by reducing the starting current through a star-to-delta connection sequence. This method helps protect motors and electrical networks from high inrush currents during startup.

They are commonly used in water pumping stations, air handling units, compressors, conveyor systems, and large industrial machinery.

Main components include the main circuit breaker, contactors, timer relay, overload relay, control relays, push buttons, LED indicators, copper busbars, wiring, and a painted metal enclosure.

Local sheet metal manufacturing panels are electrical or mechanical panels manufactured using sheet metal (metal) panels, and are used in a wide range of industrial and commercial applications. They are designed and manufactured locally to meet the needs of factories or various projects at competitive prices compared to imported ones such as instrument panels, risers and all different sizes of panels

Local & Universذal Panels

VFD (Variable Frequency Drive) Panels are control panels used to regulate the speed and direction of electric motors by varying the frequency and voltage of the power supply. They improve energy efficiency, process control, and motor protection.

Used in water pumping stations, HVAC systems, conveyors, fans, and industrial machinery requiring speed control.

Main Components: VFD Unit (Drive), Input MCCB / Circuit Breaker, Input MCCB / Circuit Breaker, Output Contactor (Optional), EMI / Line Filter, Overload Relay, Cooling System, Control Circuit.

VFD Drive PANELS

Control Panels manage and control electrical systems in industrial and commercial applications, centralizing operation and protection to ensure efficient and safe performance.

They are commonly used manufacturing lines, HVAC systems, water treatment plants, and building management systems.

Main components: MCCB/MCB, Contactors, Relays, Timers, PLC or HMI (if required), Push Buttons, Indicators, Busbars, and a Metal Enclosure.

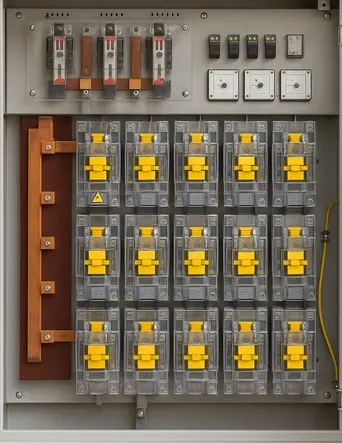

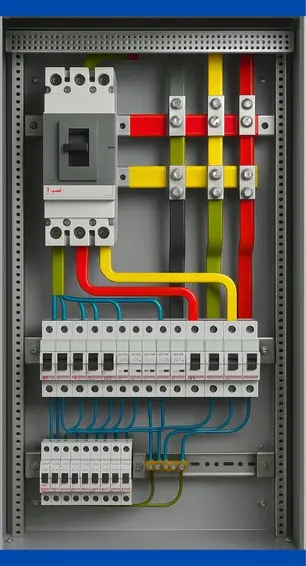

Low voltage Panels ( Distribution Panel)

Low Voltage (LV) Panels distribute and control electrical power up to 1000V AC, serving as the main point for safe and efficient power distribution in industrial, commercial, and infrastructure facilities.

They are commonly used main distribution boards (MDBs), sub-main distribution boards (SMDBs), motor control centers (MCCs), and power distribution systems in buildings and plants.

Main components: Incoming and Outgoing MCCBs or ACBs, Busbars, Protection Relays, Meters (for voltage, current, power), Control Relays, Indicators, and a Metal Enclosure.

Star/Delta Panels

Pillars & Coffrets are outdoor enclosures for low-voltage power distribution, designed to safely supply and protect electrical networks such as street lighting and public utilities from environmental conditions.

They are commonly used street lighting networks, residential compounds, outdoor installations, and public service areas.

Main components: Circuit Breakers, Fuses, Contactors, Terminal Blocks, Busbars, and Weatherproof Enclosures made of metal or reinforced polyester.

Protection Panels

Protection panels

Protection Panels safeguard electrical systems from faults like overloads, short circuits, and voltage fluctuations by monitoring the network and isolating faulty sections to maintain stability and safety.

They are commonly used substations, distribution networks, industrial plants, and power generation systems.

Main components: MCCB/MCB, Protection Relays (Overcurrent, Earth Fault, and Under/Over Voltage), CTs, PTs, Control Relays, Indicators, Busbars, and a Metal Enclosure.

Power Factor Correction

- Power Factor Correction (PFC) Panels improve electrical system efficiency by maintaining the power factor near unity through automatic control of capacitor banks.

- They are commonly used factories, workshops, HVAC systems, and pumping stations.

- Main components: MCCB or MCB, APFC Relay, Capacitor Banks, Contactors, Fuses, Busbars, and a Painted Metal Enclosure.

Motor Control Panels

- Motor Control Panels are used to control and protect electric motors in industrial and commercial applications. They centralize motor operation, monitoring, and protection to ensure efficient performance and safe operation.

- Manufacturing plants, HVAC systems, water treatment stations, and pumping systems.

- Main Components: Circuit Breakers, Contactors, Overload Relays, Control Switches, LED indicators, Soft starter, VFD and Bus bars.

Protection Panels

- Protection Panels safeguard electrical systems from faults like overloads, short circuits, and voltage fluctuations by monitoring the network and isolating faulty sections to maintain stability and safety.

- They are commonly used substations, distribution networks, industrial plants, and power generation systems.

- Main components: MCCB/MCB, Protection Relays (Overcurrent, Earth Fault, and Under/Over Voltage), CTs, PTs, Control Relays, Indicators, Busbars, and a Metal Enclosure.

Pillars & Coffrets

- Pillars & Coffrets are outdoor enclosures for low-voltage power distribution, designed to safely supply and protect electrical networks such as street lighting and public utilities from environmental conditions.

- They are commonly used street lighting networks, residential compounds, outdoor installations, and public service areas.

- Main components: Circuit Breakers, Fuses, Contactors, Terminal Blocks, Busbars, and Weatherproof Enclosures made of metal or reinforced polyester.

Low voltage Panels ( Distribution Panel)

- Low Voltage (LV) Panels distribute and control electrical power up to 1000V AC, serving as the main point for safe and efficient power distribution in industrial, commercial, and infrastructure facilities.

- They are commonly used main distribution boards (MDBs), sub-main distribution boards (SMDBs), motor control centers (MCCs), and power distribution systems in buildings and plants.

- Main components: Incoming and Outgoing MCCBs or ACBs, Busbars, Protection Relays, Meters (for voltage, current, power), Control Relays, Indicators, and a Metal Enclosure.

Local & Universal Panels

- Local & Universal Panels provide efficient control and monitoring of electrical systems, linking field devices with the main control system to ensure flexibility and reliable operation.

- Industrial automation systems, building management systems, water treatment plants, and infrastructure projects.

- Main Components: Circuit Breakers, Contactors, Relays, Terminal Blocks, Control Switches, and Indicator Lamps.

Control Panel

- Control Panels manage and control electrical systems in industrial and commercial applications, centralizing operation and protection to ensure efficient and safe performance.

- They are commonly used manufacturing lines, HVAC systems, water treatment plants, and building management systems.

- Main components: MCCB/MCB, Contactors, Relays, Timers, PLC or HMI (if required), Push Buttons, Indicators, Busbars, and a Metal Enclosure.

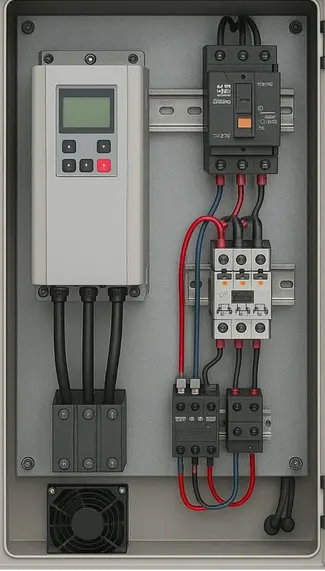

Soft Starter Panels

- Soft Starter Panels are control panels designed to start electric motors smoothly by gradually increasing the voltage, reducing mechanical and electrical stress during startup.

- Used in water pumps, HVAC systems, compressors, conveyors, and heavy industrial machines.

- Main Components: Soft Starter Unit, Bypass Contactor, Bypass Contactor, Overload Relay, Control Components, Cooling System.

Synchronization Panels

- Synchronization Panels are used to synchronize multiple power sources such as generators or transformers, ensuring balanced and stable power distribution.

- They are commonly used power stations, generator rooms, factories, and data centers.

- Main components: MCCB/ACB, Synchronizing Relay or Controller, Voltage & Frequency Meters, CTs/PTs, Control Relays, Busbars, and Metal Enclosure.

Direct On-Line (DOL panels )

- Direct On-Line (DOL) panels are used to operate small and medium electric motors directly from the power supply without reducing the starting current.

- They are used in electric pumps and irrigation systems, ventilation and air conditioning systems, simple production lines, and small elevators and hoists.

- Main Circuit Breaker (MCCB or MCB) – Contactor – Thermal Overload Relay – Start/Stop Push Buttons – LED Indicators – Additional Protection Relays – Copper Busbars and Wiring – Painted Metal Enclosure.

Star/Delta Panels

- Star/Delta Panels are used to operate medium and large electric motors by reducing the starting current through a star-to-delta connection sequence. This method helps protect motors and electrical networks from high inrush currents during startup.

- They are commonly used in water pumping stations, air handling units, compressors, conveyor systems, and large industrial machinery.

- Main components include the main circuit breaker, contactors, timer relay, overload relay, control relays, push buttons, LED indicators, copper busbars, wiring, and a painted metal enclosure.

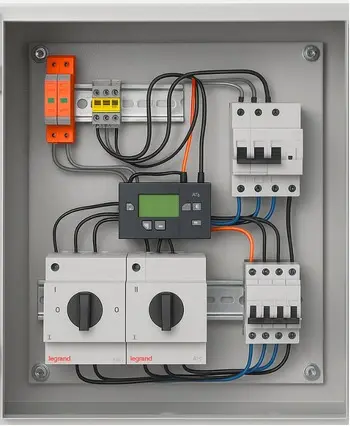

ATS Panels

- ATS (Automatic Transfer Switch) Panels automatically shift the electrical load from the main source to a generator during power failure, then return to the main source once power is restored — ensuring continuous operation.

- They are commonly used hospitals, data centers, factories, commercial buildings, and critical facilities requiring continuous power availability.

- Main components: Automatic Transfer Switch, MCCB/ACB, Control Relays, Voltage Monitoring Relay, Timer, Busbars and Wiring, and a Painted Metal Enclosure.

VFD Drive Panels

- VFD (Variable Frequency Drive) Panels are control panels used to regulate the speed and direction of electric motors by varying the frequency and voltage of the power supply. They improve energy efficiency, process control, and motor protection.

- Used in water pumping stations, HVAC systems, conveyors, fans, and industrial machinery requiring speed control.

- Main Components: VFD Unit (Drive), Input MCCB / Circuit Breaker, Input MCCB / Circuit Breaker, Output Contactor (Optional), EMI / Line Filter, Overload Relay, Cooling System, Control Circuit.

International Organization for Standardization

Testing, Quality, and Safety

Panel Builder

Certified Components

Two year warranty

Proactive Follow-Up & Support

Metal Products for Electrical Panel Manufacturing

Electrical Panels

All types for various applications.

Metal Products Manufacturing

Custom sheet metal & stainless

steel panels per drawings and dimensions.

Cable Trays

Various sizes and types.

Triple M Machines

Fiber Laser Cutting Machine

Cutting up to 20mm.

Copper Forming Machine

Punching, Bending & Cutting up to 10 mm thickness and 150 mm width.

CNC Bending Machine

160 Tons Capacity.